|

Picture Frame |

| Overview |

At UNIQUEPROJECTS we focus on providing our users

with unique project plans. To keep our endeavor afloat, however,

we occasionally work on other projects. Here is an overview of a large picture frame that we made for a client. |

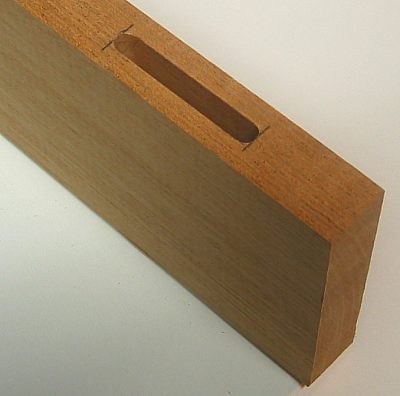

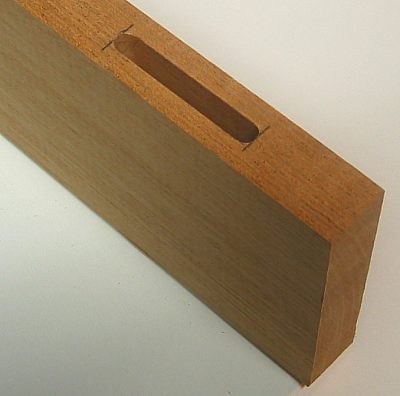

| This is a arts and crafts style frame that I am making for the

same client to commissioned the bed that I made last year. The

design is straightforward with a few details including square pegs and a cloud lift on the top

rail. I began by

squaring all of the mahogany stock and then progressed to the mortises.

I have found that it is best to make the mortises first and then to fit the tenons to them. Using

a square, I carefully mark the beginnings and ends of the mortises. Note that the mortise width is

approximately 1/3 the thickness of the material.

|

|

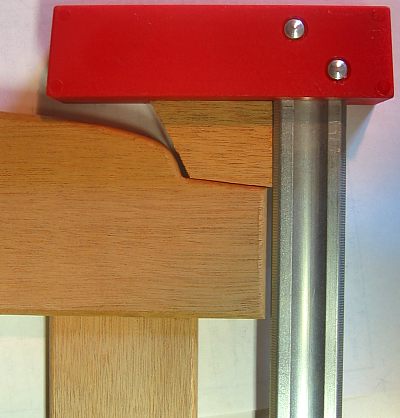

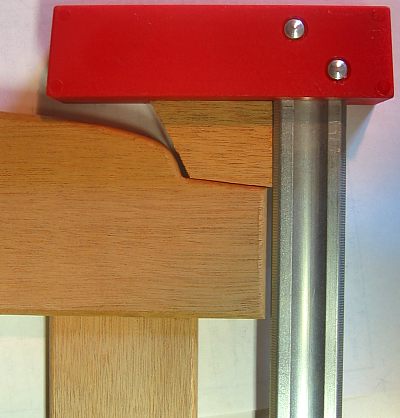

| I make tenons on a table saw with a dado set and crosscut sled.

I simply clamp a square stop to the

right of the blade; the dimension between the stop and the edge of the blade sets the length of

the tenon. Then, with repeated passes, I remove more and more material until the board

has reached the stop. Flip the board 90 degrees and repeat until you have created the tenon.

The image on the right shows two tenons. The first one is a tenon as it

looks right after using the table saw. Notice that there is a little wood left on the top (and bottom) of

the tenon; I use a chisel to remove these small tabs. This simple extra step ensures that all the pieces

will align properly. The tenon shown on the right is cleaned up: I have removed the small wood tabs

at the top and bottom of the tenon, rounded off the tenon so it will fit in the mortise, and created

a small chamfer at the end of the tenon so it will slide into the mortise easily during assembly.

|

|

|

|

| The cloud lift detail is common in arts and crafts style

design. I marked the desired curve and cut it out on the bandsaw. I saved the scrap from

this cut for a later step. After disk sanding the curve to the final shape, I rounded over

all the edges with a 1/8" (3mm) rounding over bit on a router table.

|

|

| I try to do as much sanding as possible before assembly because

it is much easier to sand loose pieces. After dry fitting the four pieces, and confirming that everything

was square, I glued everything up using polyurethane glue and long bar clamps. Notice the scrap

of wood that is used to match the angle of the cloud lift. I check for squareness of the frame

by measuring diagonally from one corner to the other, and comparing this dimension to its

counterpart: if they are identical, then the frame is square. Also notice that there is a reveal

with respect to the stiles and the rail. This is another common detail used in arts and crafts

design. I created this by simply planing the stiles just before edge rounding and assembly.

|

|

| After the glue has cured, I completed a final detail: square plugs.

I start the process by making the mortises for the plugs. The assembled frame was too large and bulky

for the mortising machine, so I made the mortises by 'hand'. First I used a hand drill to drill an undersized hole

in the desired location. Then I took a hollow chiseling mortise (without the drill in the center)

and aligned

it to the hole I just drilled and confirmed that it was not askew. A couple of taps with a

rubber mallet creates a nice square hole. I clean out the rest of the mortise alternating

between a hand chisel and a few more taps on the hollow chiseling mortise. For the plugs, I simply cut

slightly oversized plugs with a bandsaw, and then sand slight tapers on the edges so the plug lightly

compresses into the mortise - this makes for a great fit. The client requested flush plugs so after

the glue dried, I cut them with a flush cut saw and sanded until flush. |

|

| Next I created a rabbet for the clear plastic sheet,

matboard and photograph that will be displayed in this frame. I routed the rabbet on a router

table and I will leave the corners of the rabbet rounded; note that these can easily be squared off

with a chisel. If you leave the rabbet rounded, the matboard and plastic will also have to be rounded, but

I think this is a detail that the client will appreciate. After final sanding, I coated the frame

with three coats of antique oil.

|

|

|

|

| Here is a detail view of the upper left corner of the frame. Antique oil gives

the wood a beautiful lustre that the photographs do not seem to capture. I used two mat boards

to embellish the overall look of the photograph. I prefer plexiglass over glass to protect the picture; its

safer and is easily cut with woodworking tools. The client was very pleased with the completed frame.

|

|